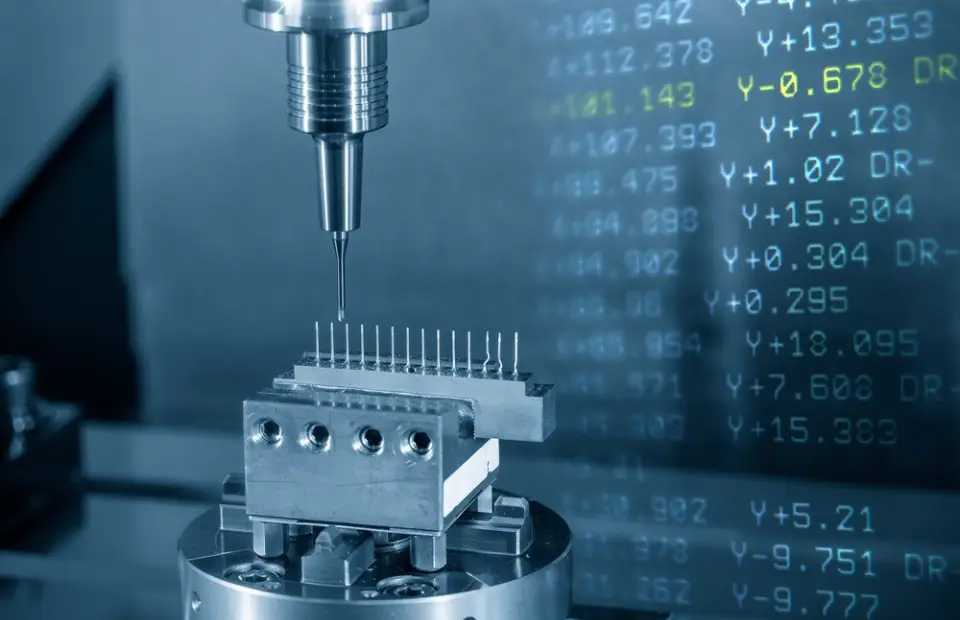

CNC (Computer Numerical Control) Machines are computer-controlled manufacturing tools. They are used to automate and precisely control the movements of tools and machinery in various manufacturing processes.

Computer numerical control (CNC) is a manufacturing method that uses a computer program to control machine tools. CNC machines have revolutionized processes, enabling industries to produce high-quality, complex components and products with speed and precision.

- History of CNC Machining

- How Many Axes Does a CNC Machine Have?

- CNC Machining is a Subtractive Process

- Working on a CNC Machine

- How is a Computer-Aided Design (CAD) created?

- What is done in the Computer-Aided Manufacturing (CAM) Process?

- What Steps are done in Computer Numerical Control (CNC)?

- Conclusion

- Frequently Asked Questions on CNC

History of CNC Machining

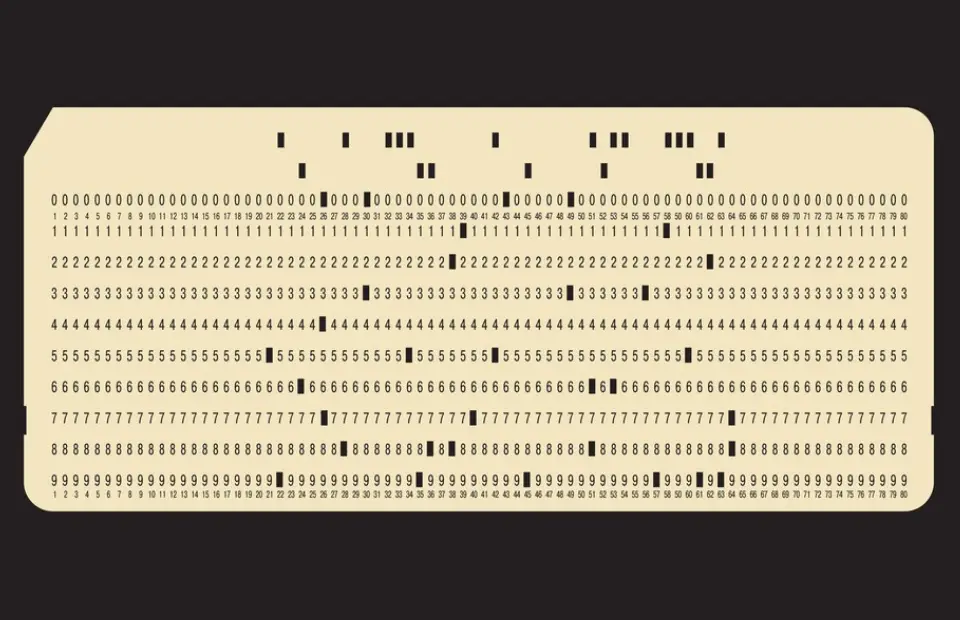

The precursor to CNC technology was Numerical Control (NC), which used punched cards with holes to control the movement of machine tools. This technology was developed primarily during World War II to automate the Manufacturing of parts for military equipment.

In 1952, the first commercially successful CNC machine, the “UNIVAC 1105,” was developed by John T. Parsons and MIT, which stands for Massachusetts Institute of Technology.

Then, over time, CNC machines kept evolving. Until the 20th century, it became an integral part of many manufacturing industries.

Now in the 21st century, CNC technology has improved machine design, control systems, and Software. CNC machines are now capable of handling a wide range of materials and allow the development of customized parts.

How Many Axes Does a CNC Machine Have?

These machines have different axes for proper movement and controlling the cutting process. Some machines have only two axes (x and y), some have 2.5(x,y and a little bit of up and down movement), some have 3 (x,y, and z), some have five axes(x,y,z, and two rotational axes).

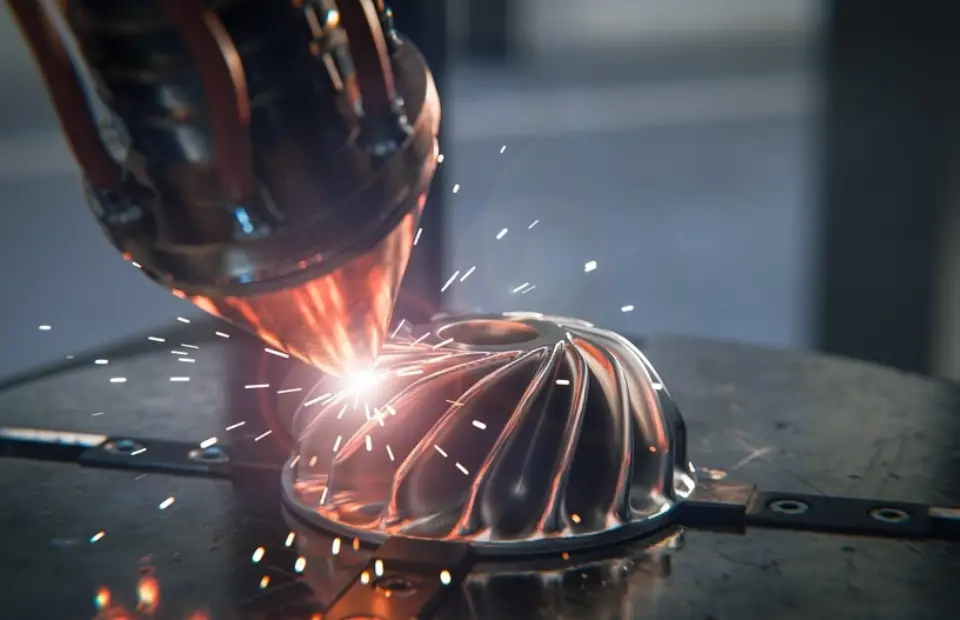

CNC Machining is a Subtractive Process

A computer design file can be used by engineers, machinists, or makers in two ways.

One way is CNC machining, like other machining processes, is a subtractive process where the material is removed from a stock.

3D printing, on the other hand, is an additive process because, here, the material is added to form a shape.

Working on a CNC Machine

First, you come up with a really clever design on the computer, which is called CAD (computer-aided Design).

Second, you take the Design and create instructions that describe how to carve it. This process is called CAM (Computer-Aided Manufacturing); more on that later.

Third, we need to hand these instructions over to the machine. A digital interface is typically used for this purpose. When we are ready, we may initiate the cutting process by pressing the “start” button. This part is known as CNC(Computer Numerical Control).

Of course, each of the three sections has many different subsets. Each section will be discussed in more detail below.

How is a Computer-Aided Design (CAD) created?

The first step of the process is often referred to as CAD, which stands for Computer-Aided Design. It simply means we’re using computer software to create the Design.

This is where most beginners start to sweat. But I promise you, it’s not as complicated as it seems.

Which Software is Used In CAD?

For starter projects, you can use simple 2D graphic programs like Inkscape or Illustrator. The other end of the spectrum is professional-level CAD programs like SolidWorks or Fusion 360. In-between programs are created specifically for CNC machines like CAMLab, Carbide Create, and Easel.

Which Software you choose will also depend on the type of cut you’re trying to create. Most CNC projects use one of three different cutting strategies.

Type Of Cuts

First, we have 2D cuts. These are when we simply have the machine trace an object and cut it out in things like letters and basic shapes.

Second, we have the three-dimensional cuts, where the machine uses all three axes at the same time. This approach is preferred for more involved tasks.

In between these two, we have 2.5D. This is when we’re just following simple shapes like regular 2D cuts, but we tell the machine to cut more profoundly in a specific area. It’s not an accurate 3D cut because the Z-axis never moves at the same time as the Y or X-axis.

What is done in the Computer-Aided Manufacturing (CAM) Process?

Once we’ve created the Design, we need to create the instructions for the machine. That means we’re using a computer to control a machine that can manufacture things. Remember, CAD is Design, and CAM is manufacturing. Fusion 360 is my personal software choice because it does CAD and CAM in the same piece of Software. It’s also free for users to use.

The first step when creating our CAM instructions is to define our material, enter the dimensions, and then we need to choose our cutting tool.

Our blade needs to be narrower than the materials we’re slicing. A 1/4-inch end mill physically can’t drill a 1/8-inch hole. So we need to tell the Software which tool we’re using to make sure it will work with our shape.

What Is The Difference Between Speed And Feed?

We can define the speeds and feeds. This concept is one that often confuses newbies, but it’s much simpler than most think.

Cutting speed refers to how fast the cutting tool moves relative to the material. It’s like a speed limit.

The feed rate is defined as the distance the tool travels during one revolution of the tool.

Toolpaths

Once our material and bit info is defined, we need to write the body of the instructions. This is where we tell the Software what shapes to cut out. We refer to these as the toolpaths or the path through space that our cutting tool follows. How you achieve this will differ from Software to Software.

The most significant advantage of CAM software is that we can simulate our cut before sending it to the machine. This helps us catch any potential problems before we plough through our material or, even worse, break the machine.

When the machine doesn’t do what the beginner expects, they usually give up. However, the issue is that the machine does exactly what it is told to do. When something goes wrong, it’s because we gave it an instruction that we didn’t mean to. We’re done creating our instructions once our setup and toolpaths are complete.

What Steps are done in Computer Numerical Control (CNC)?

At this point, we need to hand them over to the machine. The current state of the instructions is that they are stored on our computer and unknown to the machine. To get the instructions to the machine, we’ll need to export them in a language that the machine can understand. Most machines read something called G-code.

What is G-code?

The “G” stands for Geometric. The great thing about G-code is that you don’t ever have to learn how to write it, as the Software does it all for you. However, as you get more into the world of CNC machines, you’ll find having a basic understanding of G-code will help you avoid unwanted problems.

Put simply, G-code is written out to tell the machine where to travel to. The G-code includes lines of code that plot each shape of the Design.

Giving the G-code to the Machine

Once we have our G-code, we have to find a way to get it to the machine. Most machines often have a control box that includes a microcontroller, such as an Arduino.

That means we’ll need to use our computer to communicate with it.

Depending on the machine, this can be done straight from your Software using a plugin, or we can use GRBL, which is an open-source CNC controller. Our CAM software’s output of G-code is now accessible.

Putting The Material In The Machine

We need to strap in our material. We can simply screw in the material, strap it in place with clamps, use double-sided tape or a vacuum table that sucks the material down. We also need to place the appropriate bit in the collet. Remember, this has to be the same as what we defined in the CAM software. Next, we need to place the machine in its starting position.

With most machines, we’ll have to do this manually. Most machines also require us to manually adjust the speed of the router and turn it on. We can then simply hit the run or play button, and the machine starts to cut.

Remember, if the machine travels where we don’t want it to, then it’s because we told it to do something that we shouldn’t have. Most errors are caused by including features or settings without knowing it.

Conclusion

CNC machines are of great advantage. They help us to do a lot of work in minutes. They have transformed the industry of Manufacturing. This machine has made it easy to develop complex structured parts of robots. Indeed, advanced robotics like Robotic Surgery Advancements in Health Care, genuinely rely on these types of machines.

Having these types of advanced machines reduced the error factor to a great extent. Once you get experience with how to use it, you can create a lot of things.

Make sure you operate these machines carefully. A small technical error can cause great destruction if not fixed on time.

Frequently Asked Questions on CNC

What types of machines can be controlled using CNC technology?

CNC technology can control a wide range of machines used in manufacturing, including milling machines, lathes, routers, plasma cutters, laser cutters, 3D printers, and more.

What are the primary components of a CNC system?

The primary components of a CNC system include the CNC controller (computer), machine tool or equipment, servo motors or stepper motors, feedback sensors (such as encoders), and the interface for inputting instructions (such as a control panel or computer software).

Can CNC technology be used for both prototyping and mass production?

Yes, CNC technology is suitable for both prototyping and mass production. It offers versatility in producing one-off prototypes as well as large batches of identical parts with consistent quality and accuracy.

What are some common applications of CNC technology across industries?

Common applications of CNC technology include the manufacturing of automotive components, aerospace parts, medical devices, electronics, furniture, moulds and dies, signage, architectural elements, and custom machinery.